Vehicle diagnostics have become an integral part of automotive maintenance and repair, allowing mechanics and vehicle owners to quickly identify problems. The terms OBD and OBD2 (also called ODB-II or ODBII ) often emerge in conversations about vehicle diagnostics. OBD stands for On-Board Diagnostics, which is a computer system within a vehicle that provides real-time data as well as a standardized series of diagnostic trouble codes (DTCs) which allows the user to quickly identify and remedy malfunctions within the vehicle.

While OBD systems have been in use since the 1980s, the technology has evolved, leading to the development of a second, more advanced generation known as OBD2. Introduced in the mid-1990s, OBD2 offers greater capabilities and was designed to be universal across most newer vehicle makes and models.

The main difference between the two systems lies in the standardization and the range of diagnostic capabilities. OBD2 systems provide a standardized trouble code list and a common connector which applies to all compliant vehicles, thereby simplifying the diagnostic process. Understanding the distinctions between OBD and OBD2 is essential for those involved in automotive diagnostics and for those seeking clarity on the tools and systems they are using or considering for use.

Evolution of On-Board Diagnostics

The on-board diagnostic systems have profoundly changed the way vehicle performance is monitored and issues are diagnosed. These advancements have made diagnostics less cumbersome and more precise, aiding both technicians and vehicle owners.

The Genesis of OBD

The concept of on-board diagnostics, or OBD, arose as a response to the need for a standardized method of diagnosing vehicle-related issues. These systems were designed to monitor and report on the health of various vehicle components, primarily to control emissions. California led the charge in the 1960s, implementing regulations that would eventually require all vehicles to include some form of diagnostic systems.

OBD1: The Early System

OBD1 was the initial standardized electronic system introduced in the early 1980s. Vehicle manufacturers began to include basic diagnostic functions to manage engine performance and to ensure compliance with emission standards. OBD1 systems offered rudimentary trouble codes, which could be accessed using proprietary tools and methods specific to each manufacturer. However, OBD1’s capabilities were limited and lacked the uniform approach that later systems would provide.

OBD2: The New Standard

The advent of OBD2 marked a significant leap in vehicle diagnostics, offering a unified system for monitoring emissions and engine performance. This standardization simplifies troubleshooting and ensures more efficient emission control.

Standardization Benefits

OBD2 is a federally mandated standard that replaced the earlier, make-specific OBD1 systems. It ensured that all vehicles manufactured from 1996 onwards in the United States featured a uniform diagnostic protocol with a 16-pin diagnostic connector. The key benefit of standardization is that it enables compatibility with a wide variety of diagnostic tools, thereby simplifying the process for mechanics and technicians to identify issues across different vehicle makes and models.

Enhancements Over OBD1

- Extended Diagnostic Capabilities: OBD2 systems provide more comprehensive diagnostic codes than OBD1, offering detailed information about a vehicle’s engine and other systems.

- Real-Time Data: They monitor data in real-time, giving immediate feedback, which is crucial for detecting intermittent problems.

- Emissions Monitoring: Specifically, OBD2’s enhanced focus on emissions helps in meeting both California and federal universal standards, thereby assisting in better environmental protection.

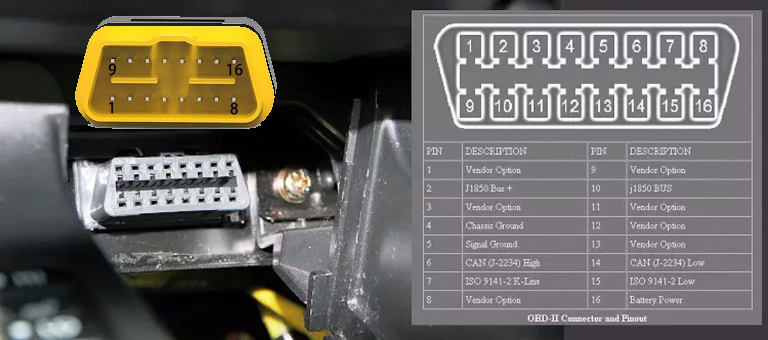

The OBD2 Interface

The OBD2 interface, which is the standard 16-pin connector located typically near the steering column, presents a streamlined way for vehicles to communicate with diagnostic equipment. Each pin serves a specific function, such as providing power or transferring data, and is universal across most vehicles. This ensures that the same diagnostic equipment can be used regardless of the vehicle’s make or model, highlighting OBD2’s utility as a standardized diagnostic system.

Key Differences Between OBD and OBD2

The evolution from OBD to OBD2 revolutionized automotive diagnostics, improving standardization, the range of diagnosable systems, and access to real-time data.

Connector and Protocol Variations

OBD, also known as OBD1, uses manufacturer-specific connectors and protocols, resulting in a lack of standardization. Each automaker could develop their own connectors and communication methods. In contrast, OBD2 is a standardized system, ensuring that any OBD2-compatible tool can interface with vehicles from different manufacturers.

Access to Real-Time Data

OBD1 systems provide limited diagnostic capabilities and do not typically offer real-time data. On the other hand, OBD2 allows for comprehensive monitoring and the ability to access real-time data, enabling more accurate and immediate diagnostics.

Range of Diagnosable Systems

OBD1 systems were typically less comprehensive in the range of diagnosable systems. With the introduction of OBD2, often referred to as OBDII, the scope of diagnostic checks expanded significantly. OBD2 is more comprehensive, monitoring a broader array of vehicle systems including emissions, engine performance, and overall vehicular health.

Diagnostic Tools and Their Functionality

Diagnostic tools are essential for interpreting the data produced by a vehicle’s On-Board Diagnostics (OBD) system. These tools vary in complexity and capability, from basic code readers that can decipher trouble codes to advanced scanners that provide in-depth diagnostics.

OBD1 and OBD2 Scanners

OBD1 scanners are designed for vehicles manufactured before 1996 and are manufacturer-specific, meaning they may only work with certain makes or models. On the other hand, OBD2 scanners are standardized for use with any vehicle from 1996 onward. These diagnostic tools are plugged into a standardized port and can read Diagnostic Trouble Codes (DTCs) that indicate where a fault may be occurring within the vehicle’s systems.

Code Readers and Advanced Scan Tools

Code readers are simpler devices that can read and clear codes from the vehicle’s OBD system. They provide essential information, such as the error codes themselves, but do not offer further diagnostic data. Advanced scan tools offer more in-depth data, often providing real-time monitoring, advanced troubleshooting information, and sometimes even repair suggestions. They may also display both generic and manufacturer-specific codes, giving mechanics and enthusiasts alike a more comprehensive understanding of a vehicle’s health.

Manufacturer-Specific and Generic Codes

Fault codes come in two types: generic (standardized across all OBD2 compliant vehicles) and manufacturer-specific (unique to each vehicle manufacturer). Generic trouble codes start with P0 or P2, whereas manufacturer-specific codes start with P1, P3, or P9. Diagnosing with DTCs requires a scan tool that can accurately interpret these codes to localize faults and streamline the troubleshooting process.

Practical Usage and Automotive Diagnostics

In automotive diagnostics, understanding the nuances between On-Board Diagnostics (OBD) systems is essential for accurate vehicle maintenance. Modern cars rely heavily on these systems to monitor and report various engine and emissions-related issues. OBD and OBD2 are especially critical for interpreting dashboard signals and troubleshooting vehicle issues, allowing for efficient and timely interventions.

Interpreting Dashboard Signals

The vehicle’s dashboard is a hub of communication between the car’s systems and the driver. When the Check Engine Light (CEL) or other indicator lights illuminate, OBD tools can help diagnose the underlying issue. For OBD systems, specifically OBD2, the dashboard serves as a first point of alert for drivers to identify potential engine faults or fuel system anomalies.

- CEL activation: Indicates possible malfunctions within the emission control systems and beyond.

- Vehicle diagnostics: By connecting an OBD2 device, one can extract specific trouble codes to understand the exact nature of the problem.

Troubleshooting Vehicle Issues

OBD systems, particularly OBD2, have standardized a range of trouble codes to assist in troubleshooting. This enables a systematic approach to diagnosing and resolving car problems.

- Generic vs. Manufacturer-Specific Codes: OBD2 provides a universal set of codes for common issues and additional brand-specific codes for more precise diagnostics.

- Fuel System and Emissions: OBD2 devices offer a detailed view of the car’s fuel and emissions system, ensuring that the vehicle meets legal standards and operates efficiently.

In practice, OBD2’s advanced capabilities over the earlier OBD allow for broader diagnostics, better-standardized reporting of vehicle malfunctions, and a more informed maintenance process

How can I tell if my vehicle is OBD1 or OBD2?

One can determine a vehicle’s diagnostic system type by the manufacturing date. Vehicles produced after 1996 typically have OBD2 systems, identifiable by a standardized OBD2 port under the driver’s side dashboard.

What advantages does OBD2 have over OBD?

OBD2 provides a universal protocol for diagnostic trouble codes, enhancing compatibility across different vehicle makes and models. It also offers more advanced troubleshooting capabilities than the earlier OBD systems.

Can an OBD2 scanner be used on a vehicle with an OBD1 system?

OBD2 scanners are not backward compatible with OBD systems due to differing communication protocols and connectors. Thus, an OBD2 scanner cannot be used on a vehicle with an OBD system.

What are the key differences in the diagnostic capabilities of OBD1 and OBD2?

OBD2 systems offer more comprehensive diagnostic features, including real-time data, standardized trouble codes, and monitoring of almost all engine controls. OBD1 and OBD2 have significant differences in standardization, features, connectivity, and reliability.

Are all modern vehicles equipped with OBD2 ports?

Since 1996, it has been a requirement for all cars sold in the United States to be equipped with OBD2 ports. Consequently, the vast majority of modern vehicles on the road today are fitted with these ports.

What should I consider when choosing between an OBD1 and OBD2 scanner?

Selecting a scanner depends on the vehicle’s diagnostic system. For vehicles manufactured before 1996, an OBD1 scanner is necessary, while for newer vehicles, an OBD2 scanner is appropriate. Consider the scanner’s compatibility, features, and the level of diagnostic detail needed.